A new report by Eunomia Research & Consulting, commissioned by Amcor, Tomra and others, analyses how sorting technology using markers and object recognition can contribute to the circularity and traceability of plastic packaging recycling in Europe.

The report, entitled 'Advanced Sorting for Circularity', states that for many types of plastic packaging, further optimisation of existing sorting technologies is likely to be sufficient to improve circularity. To address the remaining sorting challenges, object recognition may be the most cost-effective advanced technology to enable greater circularity, even compared to the marker system.

The plastic packaging industry is facing increasing demand for greater sustainability, with a particular focus on increasing recycled content and promoting a circular economy. This pressure, which varies across Europe, is mainly driven by public and governmental demands, pushing brands to adopt more sustainable practices. EU legislation also imposes specific requirements on packaging, notably with the Packaging and Packaging Waste Regulation (PPWR), which is due to come into force in 2024.

This new report from Eunomia analyses how sorting technologies using markers and object recognition can contribute to the circularity and traceability of plastic packaging recycling, particularly in the EU, Norway, Switzerland and the UK.

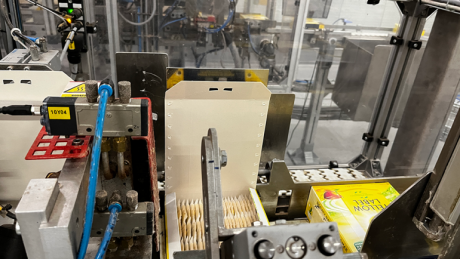

The methodology of the report is to identify polymers and packaging formats that are not adequately sorted by existing technologies to achieve circularity. It then evaluates new technologies (i.e. advanced sorting technologies) that can classify and sort these types of post-consumer plastic packaging. Several sorting technologies based on sensors and markers are also examined. Three of these are selected for detailed cost and performance modelling: object recognition, chemical markers and digital watermarks.

The study focuses on sorting types that provide raw material suitable for mechanical recycling processes, which in turn produce material suitable for packaging manufacturers. The results cover the circularity of rigid and flexible plastics, traceability and implementation. These findings clearly point the way for targeted investment and innovation in sorting technologies, highlighting the importance of aligning technology choices with specific recycling targets and the unique requirements of different types of packaging. As the industry strives to meet EU recycled content targets, this analysis will be instrumental in driving efforts towards more effective and sustainable plastic packaging recycling practices.

All advanced sorting technologies could improve traceability, although it is reasonable to conclude that digital markers would offer superior traceability compared to object recognition. However, significantly higher investments would be required to achieve greater traceability, especially for markers that require more packaging to be marked. Furthermore, the willingness to pay more for enhanced traceability is uncertain.

It is very likely that object recognition will be adopted more quickly than marking technologies, and probably already is, as it is a more cost-effective solution. Both the plastics industry and legislators should consider whether the adoption of tagging as a mass-market solution offers sufficient added value to justify the additional cost and complex implementation process.