The packaging world is changing rapidly, and with it, printing technologies and the raw materials used must evolve. The European market is increasingly influenced by regulations and legislation that promote sustainability and circularity, while maintaining stringent product safety standards through increasingly tighter regulations.

In this context, we look at how Sun Chemical is changing and will continue to change, in the future, inks, adhesives, and coatings intended for rotogravure and flexographic printing. Packaging can no longer be viewed solely from a graphic and functional perspective but also considering its end-of-life; for this reason, Sun Chemical, supported by its significant European research, development, and application laboratories, has developed a range of solutions for packaging compatible with the latest mechanical recycling technologies.

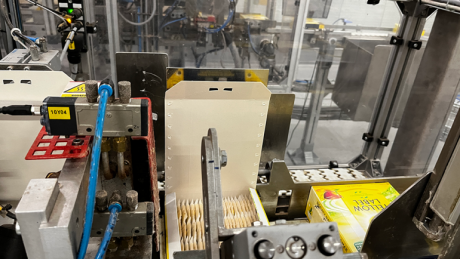

A new generation of solvent-based inks, completely free from nitrocellulose, suitable for both flexographic and rotogravure printing, as well as for external printing and lamination, is undoubtedly one of Sun Chemical’s latest successes in the liquid ink sector. The series has been designed to offer the highest quality printing, even with low line screen values, great versatility of use, and excellent performance in laminated structures, even after thermal processes such as pasteurisation and sterilisation. The series stems from a strong synergy between Sun Chemical’s integrated R&D laboratories: from the synthesis of the most suitable polyurethane resins to the search for high-performance pigments, the formulation of next-generation adhesives, alongside the specific expertise of ink formulators for packaging.

The challenges presented by the packaging market are undoubtedly becoming increasingly ambitious, but Sun Chemical, which has always anticipated trends, has once again managed to turn them into great opportunities. In fact, even in water-based product technology, a new series of second-generation inks has been developed for printing on plastic surfaces, offering extremely high image definition, high chromatic yield, and low consumption, perfectly aligned with the latest food packaging regulations and the guidelines steering the world towards a circular and sustainable economy.

Among the innovations Sun Chemical is introducing to the market are lacquers and barrier adhesives, which, when combined appropriately, offer the possibility of developing packaging with excellent water vapour and oxygen barriers, transitioning from multi-material films that are difficult to recycle to single-material, thin, fully recyclable films, biodegradable films, or even structures made from functionalised paper, in line with the recent PPWR regulation and SUP directive.

The packaging world has changed, but the range of products Sun Chemical is bringing to market is certainly not to be underestimated; experience and transformation is the motto that guides the company’s technicians every day in finding innovative solutions that can make a difference.