Davide Miserendino

“ICO has an interesting history: starting out in the 1950s as a small box factory, and then vertically integrating cardboard and paper production before finally arriving at the finished product with the addition of digital printing, is something really special. The added value of this fantastic company lies in its creativity and expertise with the materials.” These are the words of Andrea Tempesta, business developer of ICO Lab, a department dedicated to the design of POP materials within this Abruzzo-based company. ICO is a solid benchmark in Italy for the production of corrugated cardboard and its conversion into packaging and displays, boasting an almost textbook circular economy model.

Practical and sustainable solutions

ICO is a flourishing company whose ICO Lab sprang from its natural need to project itself forward and feed its production potential. Demonstrating dynamism, the laboratory quickly conceived numerous projects, some even leading to patent applications. The cornerstones of the department are its willingness to listen to customers and its ability to come up with original solutions to meet their needs, thanks to strong technical skills in materials design and engineering.

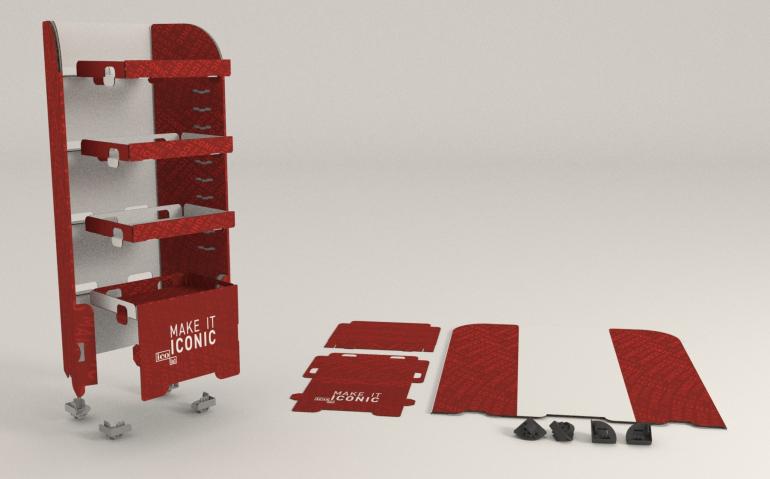

Tempesta shows us a display designed to offer an extremely economical solution for promotional campaigns involving low-cost products with high rotation. He explains: “This design, which we have called ‘Cover-display-box-on-box’ , was conceived to provide maximum freedom to customise POP through the cover, which is the only element needing graphics. Using our digital technology, it can be printed in small volumes and with variable features; in other words, it is possible to include different subjects in the same production batch. The advantages in terms of both the speed of creation and the possibility of modifying the graphics, which will still be of high quality, are evident.

Then there are certain basic design requirements that demand a creative approach. For example, we have designed, and had made, a support in recycled and recyclable plastic with bidirectional wheels to be fitted under the base of our displays. Called Pop-Wheels, this solution makes the display easier to move, and thus meets a need of, among others, the pharma sector, which prefers displays on wheels, while at the same time offering a system that is economically sustainable.”

Customers at the heart

The sales manager of ICO, Alessandro Pelone, completes the picture.

“Attention to sustainability is a must for us and for our customers: recyclability is one of our strengths and something to which we are highly committed, focusing on mono-material design and using water colours even for digital printing,” he says. “Furthermore, we offer integrated packaging design support that takes into account the specific aspects of both the logistics and the particular in-store dynamics. In practice, we work together with our customers, remaining at their side throughout all the stages in which they may need us: for us, satisfying customer needs is a mission.”