ACMA, a Coesia Group company specializing in packaging solutions for consumer goods, is preparing for a 2021 full of challenges and commitments, involving practically all its activities.

Primary packaging: many solutions for an increasingly “green” process

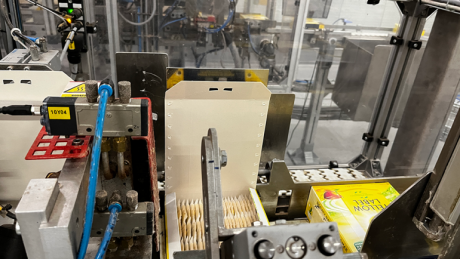

ACMA offers a portfolio of machines suitable for the packaging of the main types of consumer goods, from Home & Personal Care to Tea, through Bakery and Confectionery. ACMA machines respond to the sustainability needs expressed with increasing strength by the market; for example, the wrappers dedicated to confectionery allow thermal sealing instead of glue, while the solutions for the packaging of tea in double lobe bags use an advanced system for the closure by knot, while offering the possibility to use bio-sustainable wrappers.

ACMA machines also make it possible to create packs with a compact layout, optimizing the packing inside cartons and cardboard boxes. This allows considerable savings in terms of space and wrapping material. The products thus packaged allow further advantages in the downstream stages of packaging, facilitating transport and storage and contributing to the reduction of the carbon footprint of the entire process.

Ecoshell: innovation and practicality while respecting the environment

ACMA offers a wide range of eco-friendly solutions not only for wrapping but also for cartoning. In addition to the most popular types, such as Zip Top and Flip Top, ACMA is able to create a new carton format called “Ecoshell”, developed in partnership with COESIA Packaging Innovation Center.

It is a packaging characterized by an innovative design, which allows an optimal dosage of the product and a great practicality of use. Above all, Ecoshell is a cardboard solution with reduced impact, which meets the needs of consumers in markets particularly attentive to sustainability such as the U.S. and Europe. Designed with pilot applications in the Confectionery sector, for the packaging of chewing gum or candies, Ecoshell can also be used effectively in areas such as pharmaceuticals or cosmetics.

Digital technologies more and more efficient and within everyone’s reach

The design and marketing of machines was complementary to the digital transformation process undertaken by the company even before the Coronavirus emergency. In the last months, all the functions of remote assistance offered to customers have been intensified; from the realization of virtual FATs to remote diagnosis.

At the same time, the development of tools such as predictive software continues, able to anticipate what will be the future needs of the machines in terms of maintenance, while optimizing their operation and efficiency.

Finally, this year saw the adoption of the new HMI panel, called OptiMate; a man-machine interface characterized by extremely intuitive operating logics. The adoption of increasingly advanced digital technologies also brings benefits in terms of sustainability, making the line increasingly efficient in terms of energy and material consumption.