As an innovation driver for the packaging industry, Schubert has developed a new solution that can make automated packaging processes more sustainable: Dotlock, a technology that makes it possible to produce cardboard packaging completely without glue. Brand owners, confectionery and snack manufacturers and consumers benefit not only from sustainability, but also from many other advantages.

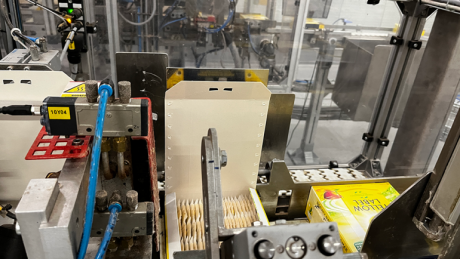

The new process, which can be used to join multiple layers of cardboard together, does not require glue as an additional material. Instead, the carton layers are perforated on one side with a needle, forming a collar on the other side, which is then pressed onto the carton to create a stable force-fit. During the Dotlock process, the carton blank is simultaneously erected, making it easy to integrate into Schubert's standard processing chain.

Schubert's aim was to achieve at least the same stability and strength with Dotlock as with a glued joint. With Dotlock, the strength normally provided by glue is achieved by the number and arrangement of perforations. For example, multiple holes can be made in corners where greater strength is required. The size of the holes also varies according to the thickness of the board. The geometry of the hole distribution is redefined for each new pack, as it is important to prevent the board from tearing if the perforations are too close together, or the joint from being too weak if the perforations are too far apart.

As a 100% glue-free packaging solution, Dotlock is fully recyclable through the paper cycle. But there are many other benefits for both businesses and consumers. For example, Dotlock paperboard packaging cannot be re-closed, which means that food products such as bakery products or confectionery cannot be tampered with. This eliminates the need for tamper-evident labels - another environmental benefit. It also eliminates the need to store glue and the heat required for processing. Dotlock can be used wherever solid board packaging is involved. The new packaging technology is ideal for trays, base lid applications and gable top packaging, for example, where food, bakery and confectionery products are traditionally packaged.