Ticinoplast, recognised as one of the most innovative companies in the flexible packaging market, will be present at Interpack (Hall 10 - 10C06) at the booth of Plastchim T, with which it is developing the PEoneer BOPE project. The company's mission is increasingly focused on the search for sustainable solutions, such as mono-material, compostable and renewable packaging films, together with other technological proposals that are an integral part of Ticinoplast's commitment to sustainability, as evidenced by the ISCC Plus certification. These are just some of the aspects highlighted by Andrea Mantillaro, Sales Director, who recently stated:

Since 2020, with the launch of the Nextfilm range of products, our commitment in terms of research and development has continued to grow. And we have developed various types thanks to important partnerships with Italian and international operators: from compostables to ones designed for producing 100% recyclable mono-material sheets, from plastic films with a reduced weight, to new films made with PCR (post-consumer recycled) resin. Specifically, to be able to produce this last type of film, it has been fundamental to have obtained the ISCC PLUS certification which implied the adoption of a corporate management system that starts from the acquisition of raw materials whose origin is declared as being from renewable sources and/or the recycling of plastic material according to a certified scheme.

From certification to the market

In practice, Ticinoplast has demonstrated that it is able to produce sustainable mono-extruded and coextruded PE films intended for finished products, which contain a percentage of ISCC-certified materials, established in the design phase. Andrea Mantillaro explained:

To achieve this objective, Ticinoplast has chosen the mass balance approach, which determines the sustainable proportion and the quantity of sustainable output product, based on the quantity of ISCC+ certified input material. Now we can develop sealable and peelable film starting from resins originating from chemical, mechanical, post-industrial and bio-based recycling (resins from renewable sources). In general terms, having established our ISCC PLUS scheme facilitates the transition towards a circular economy model in line with the goals set by the European Union in relation to sustainability, providing guarantees of transparency and traceability along the entire supply chain. For example, we have set up projects using post-consumer resins both from chemical and mechanical recycling, the latter managed through dedicated procedures, to produce more sustainable films intended for industrial applications.

Expertise and innovation

Ticinoplast was also among the first processing companies to develop certified biodegradable and compostable films, conforming to the EN 13432 European standard, thereby contributing to the creation of a supply chain characterised by high-level technologies. The films in which a lower use of plastic is a distinctive feature are certainly the expanded ones. In this regard, Mantillaro urges caution by stating:

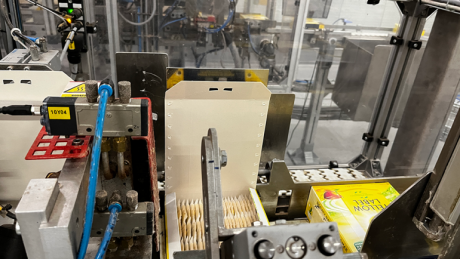

Be careful, however because, in any case, such a reduction must not affect the mechanical characteristics and sealability of the film. In this regard, Ticinoplast is developing films in which a reduction of density of up to 0.78 g/cm3 is achieved, with a relative saving of around 15% on the weight. Our expanded polyethylene films, available in both HDPE and LDPE, white or transparent, are produced on a 5-layer blister line. The technology applied makes it possible to expand only the central layer thanks to the creation of micro bubbles generated by the injection of gas in the central part during extrusion thereby enabling easy filling and physical expansion of the resin during the injection phase. The central layer remains expanded while the adjacent layers act as a barrier, maintaining the mechanical, technical and sealing properties: this is a type of film which guarantees characteristics of durability and conservation essential for flexible food packaging. It goes without saying that we have equipped ourselves with new plant in order to reach these milestones and increase our production capacity.