Eliminating non-recyclable elements from the package; guaranteeing the perfect preservation of chocolate truffles; reducing the product’s overall carbon footprint: these are the goals achieved by Sun Chemical, Qualvis and Whitakers, whose collaboration has led to award-winning packaging, in which inks and coatings make a significant step forward in food packaging safety and sustainability.

Sun Chemical has won the PrintWeek 2024 Packaging Innovation Award, in collaboration with leading packaging solutions provider, Qualvis. The multi-award-winning project at the PrintWeek Awards 2024 focused on the redesigning of the packaging for the main lines of 150g chocolate produced by Whitakers, which requested the elimination of non-recyclable elements while at the same time ensuring product integrity and shelf-life.

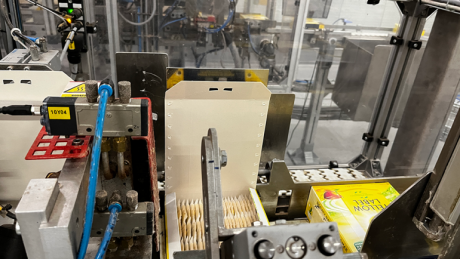

The concept has enabled Whitakers to transform the existing chocolate truffle carton containing 55% plastic into a highly recyclable lightweight fibre-based solution of the same dimensions without plastic films.

It’s innovative packaging, therefore, developed thanks to the Sun Chemical’s SunPak® DirectFood Plus highly bio-renewable direct-food contact inks combined with the SunSpec™ SunStar direct-food contact aqueous varnish. SunPak® FSP EcoPace low-migration inks have been used on the outside of the carton, coated with a SunCoat water-based OPV, further reducing the carbon footprint due to a very high bio-renewable content. This result has been made possible by using the FEP89 Black Process, which doesn’t use carbon black derived from fossil fuels. It should be noted that all the inks are cradle-to-cradle certified, and that the inks and coatings represent a significant step forward in the safety and sustainability of food packaging.

New standards, thanks to a rigorous and multiform approach

Entirely redesigned by Qualvis and Sun Chemical, the new chocolate truffles packaging is now characterized by the complete absence of plastic. The use of Sun Chemical's inks and coatings has made it possible to eliminate non-recyclable elements, specifically the outer shrink film and inner greaseproof cushion pad, which could be replaced with a fibre-based holding structure, ensuring at the same time a direct food contact safe environment, functional resistance and barrier properties of the packaging. All this, in combination with a high percentage of bio-renewable components of the inks, drastically decreases the overall carbon footprint of the product.

Qualvis’s membership of the World Land Trust scheme and its adherence to Forest Stewardship Council (FSC) certification standards has been decisive in the collaboration set up by the companies. In this way, the packaging designed for Whitakers has, in fact, exceeded environmental benchmarks: offsetting carbon emissions through the World Land Trust scheme and sourcing materials responsibly with FSC certification, the resulting packaging achieved a net-zero carbon footprint.