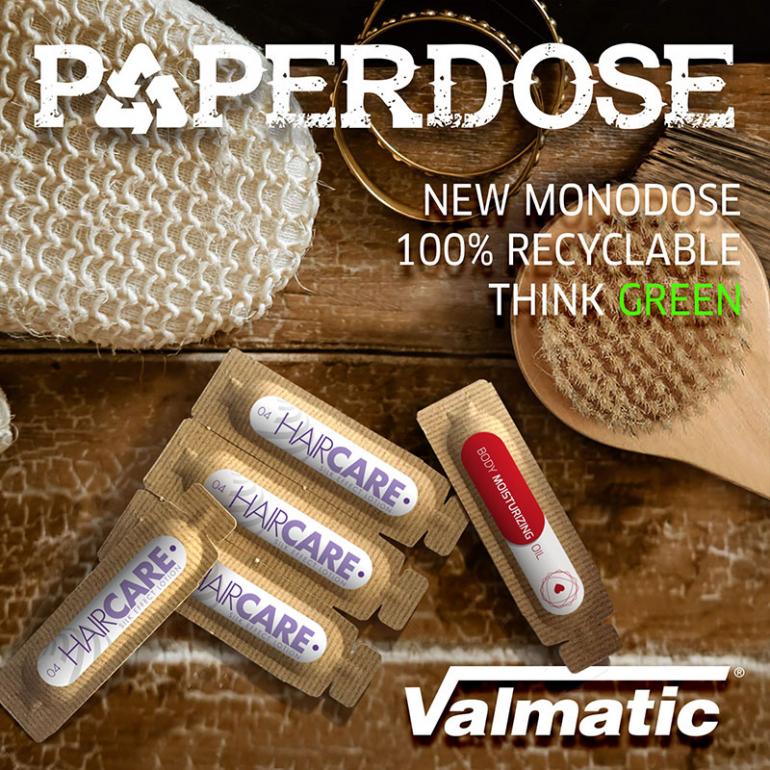

Valmatic’s vision of the circular economy: the need to protect the environment, safeguard natural resources and recover and recycle materials has led to the development of Paperdose, the thermoformed paper single-dose packaging solution that can be recycled with paper waste.

Developed through the research efforts and spirit of innovation of the Modena-based company Valmatic, an integrated manufacturer of single-dose packaging systems, the Paperdose project uses Aticelca and FSC certified paper and represents a new concept in single-dose packaging. It uses recyclable materials and combines care for the environment with the need for sustainability and green communication expressed at various levels by customers operating across all sectors, from cosmetics to food, chemicals, parapharmaceuticals and veterinary medicine.

The first 3D single-dose packaging solution made of paper, Paperdose is easy to open thanks to its shape and material and is already available in a range of sizes from 1 to 45 ml. It can be recycled as paper, allowing the raw material to be returned to the production cycle and reducing CO2 emissions.

The efficiency of sustainability. Versatility and creativity have always been Valmatic’s key strengths. Based in the heart of Italy’s Packaging Valley, the company is able to offer comprehensive solutions to the needs of customers and end consumers in terms of safety and convenience.

Valmatic has always supplied customised processing solutions for the cosmetics, parapharmaceutical/veterinary, food and chemicals markets and now more than ever is gaining recognition for its R&D work in the field of sustainable solutions. Along with the recently developed Paperdose solution, the company uses standard plastic materials to produce single-dose containers and ampoules made from up to 80% recycled plastic originating from the European post-consumer PET bottle market, as well as FSC-certified card or cartons for the production of secondary packaging.

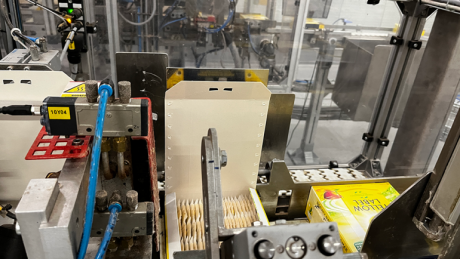

Valmatic performs all steps in the production process in-house, from the design of the machines sold all over the world to the production of the moulds and finished product packaging. This gives customers a single point of contact while assuring full control over the quality of the entire supply chain, enabling Valmatic to offer constant support and assistance for the entire duration of the working relationship.

Packaging in step with the times. The impact of the Covid-19 pandemic on living and consumption patterns has boosted the popularity of single-dose packaging for all applications. It is ideal for ensuring full compliance with hygiene regulations and for preserving the properties of the contents. To allow even small-scale producers to prepare for these momentous changes, Valmatic has decided to reduce the minimum batch order size.