The OMNI collaborative research project led by Recycleye, Valorplast and TotalEnergies to improve the circularity of polypropylene (PP) food packaging has produced groundbreaking results. The new technology, based on artificial intelligence (AI) and computer vision, combined with an efficient decontamination process, provides a high-performance, marketable solution to the challenge of mechanically recycling polypropylene for food contact applications.

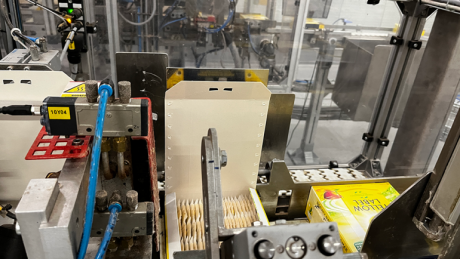

It is one of 7 projects successfully selected in October 2020 by Citeo, a mission-driven company dedicated to reducing the environmental impact of household packaging and paper, through a call for projects. After 18 months of research, Project OMNI resulted in an alternative to digital and physical marking solutions that require system-wide packaging changes. In a demonstration unit, Recycleye built and trained an AI model based on waste collected from 5 sites across France, supplied and characterised by Valorplast.

The AI and robotic sorting achieved a successful pick rate of 50% of food grade material with >95% purity. This sorting activity produced material for further decontamination in a semi-industrial pilot based on standard mechanical recycling technologies.

TotalEnergies then used its polymer expertise to produce odourless, clean rPP suitable for high-end packaging applications. The newly developed process has demonstrated the efficient decontamination of food-grade PP waste sorted by AI and computer vision, opening up new opportunities for the circularity of polypropylene packaging.

Nathalie Brunelle, Senior Vice President, Polymers at TotalEnergies, said:

This project not only demonstrates how cutting-edge technology can improve material circularity, but also paves the way for a wider range of accessible applications for recycled polymers to serve our customers. It provides a concrete response to the challenge of managing end-of-life plastics and fully supports our ambition to reach 1 million tonnes of circular polymers.