As part of environmental protection, which has now become a prerogative of all industries, the main bottling companies require innovative packaging solutions which may ensure economic and energy savings.

To meet this type of needs, thanks to an advanced CAD center for 3D design, SMI, an Italian manufacturer of bottling plants and packaging machines, has invested heavily in solutions for producing rPET bottles and for supporting companies in the study and graphic realization of a wide range of high-capacity containers which are 100% recyclable, of high quality and lightweight for saving energy and material.

In terms of size, high-capacity containers, such as 5, 8 and 10 L containers, arouse growing interest, especially in the companies that pay attention to green and cost-saving solutions. By using high-capacity bottles, in fact, fewer containers are required to reach a certain product volume and therefore, logistic, handling and disposal costs are reduced.

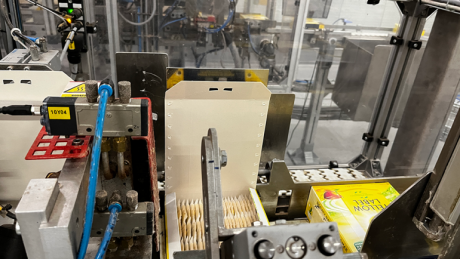

SMI has decades of experience in the manufacturing of machines for the production of high-capacity containers, as well as in the design of bottles that meet customers’ functional and aesthetic requirements. In this regard, the company develops innovative containers, such as the stackable “Neck-in-bottles”, that, thanks to a particular design of the hollow of the bottom, offer the advantage of: optimizing the space of the pallet; reducing the packaging costs because the cardboard interlayer pads are not needed; lower transport and storage costs, thanks to the higher number of bottles on each pallet; reducing the waste because the bottle necks are subject to fewer breakages during the palletizing phase; improving the aesthetic aspect of the pallet, which results more compact and that can be graphically customized.