What Gerhard Schubert is presenting this year at the interpack 2023 (Düsseldorf 4-10 May) extends well beyond forward-looking packaging technology. The innovation driver will be showcasing its latest technical advancements for the packaging industry at stand D01 in hall 14.

Some of the highlights include cobots for the rapid feeding of different packaging components on a line, an extremely compact filling machine for cosmetic products and an entirely new, efficient, resource-saving feeding system for carton blanks. Beyond this, however, the packaging machine manufacturer is busy gearing up to the challenges of the future - with a concept study for a new generation of machines, in combination with an all-new type of transport system. Together, the two promise to advance current packaging processes to the next level of automation, flexibility and efficiency. The innovative technologies are complemented by a wide range of new services for more environmentally compatible packaging.

Visitors to this year’s interpack will have an opportunity to closely examine the latest developments. The previous edition of the leading international trade fair took place in 2017. At Gerhard Schubert, the evolution is immediately apparent. The company’s presence at the trade fair clearly reflects Schubert’s vision for the future: To develop sustainable packaging solutions for tomorrow’s world. With this in mind, Schubert is presenting a portfolio with which the company is significantly expanding its far-reaching expertise in packaging machine design - in the interests of customers and the environment - and ideally setting itself up for the future. Intrinsically linked to this is the company’s Mission Blue Sustainability Initiative, the defined goals of which are gradually becoming tangible measures - within the company itself, as well as in the consulting and services provided to Schubert customers.

A multitude of services to deliver forward-looking packaging solutions

These services include the new five-point Packaging Perspectives programme which includes bundled Schubert expertise, packaging development, testing facilities at the company’s technical centre and laboratory, as well as customised consulting services to ensure the best possible mix of materials, packaging and machine. On request, the Packaging Perspectives experts can provide support in switching to more sustainable packaging, for example with glue-free box alternatives or more environmentally friendly flow-wrap films. Schubert Service will also be on site to present the new customer portal and explain the company’s Digital Care Services for data analysis and process optimisation. Schubert Packaging Systems will be represented at the stand with its three divisions - Pharma, Schubert Consulting and Turnkey Solutions - and showcasing its areas of expertise. The Schubert Additive Solutions subsidiary will also be demonstrating its Partbox solution and 3D printing.

Five exhibits with cutting-edge technologies

Flexibility, efficiency and availability remain at the heart of Schubert’s robot-based modular technology. Through many demonstrations, visitors to the stand will have an opportunity to see for themselves - live and in action - how Schubert combines its proven approach with forward-looking concepts for new packaging processes.

The tog.519 cobot: Highly flexible automation

Perhaps most striking at the Schubert stand are the new Schubert tog.519 cobots, now ready for series production, which are being presented for the first time to an international trade fair audience. On an all-new type of cosmetics filling machine, two of the cobots will be taking over the feeding of various packaging components. A separate cobot will be processing bars, chip bags or highly reflective pouches, demonstrating the advantages of its unique AI. With the tog.519, Schubert is extending packaging process automation beyond the packaging line itself. The mobile, free-standing or optionally housed robots are ideal for picking up unsorted lightweight products via pick & place and processing them at up to 90 cycles per minute. The AI-supported programming and image processing are conceived so cleverly that customers can change formats themselves in no time at all without any prior programming knowledge. Basically, the new product simply needs to be passed through the cobot’s vision system. Flexible work locations, a wide variety of pick & place tasks, high process speed and very simple operation are the advantages cobots offer to manufacturers in a wide range of industries.

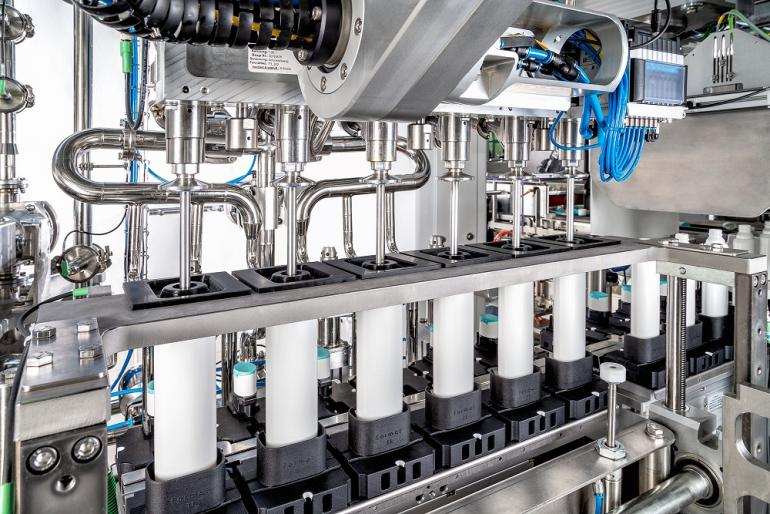

A cosmetics line for Börlind

A more compact line saves resources and reduces the carbon footprint, both in manufacturing and in the further production process. Schubert will be demonstrating just how compact a filling process can be with a recently developed line for cosmetics manufacturer Börlind. On an incredibly compact 2 x 4 metre space, liquid cosmetics are filled either into glass bottles with screw pumps or glass jars with screw caps - then closed, weighed, sealed and checked. Two Schubert cobots automatically and very gently feed the individual packaging components to the machine via pick & place. Using a recently developed transport system that complies with the Hygienic Design Standard and is suitable for applications involving liquids such as perfume, the packaging materials are then transferred to two alternating filling stations in a way that is exceptionally space-saving. The Schubert image processing system ensures all necessary quality controls, including checking breakage at the edges of the glass jars. Quick set-up times for the various formats and 3D-printed format parts guarantee even more flexibility. The modular machine concept, typical of Schubert’s approach, is ideal for adding further process steps directly to the filling line. For example, labelling and end-of-line packaging can be integrated in order to map the entire packaging process seamlessly and fully automatically in a single line.

Blanks directly from the pallet

When the blanks magazine runs empty, machine operators need to react quickly to avoid unnecessary interruptions. With the new Schubert TLM Comfort Feeder, this is now a thing of the past, as can be seen on a bar packer at the trade fair. All it takes is to place the entire pallet with the blanks - still in the blank sheet - into the machine. An F4 robot then pulls the blanks one by one directly from the sheet and feeds them into the erecting process at a rate of 60 cycles per minute. This process also has another advantage: the sheet cutting process can be optimised to maximise packaging material utilisation, saving material, resources and costs. The combination of a new type of sheet indeed, high erecting capacity, and loading and sealing in a small space offers Schubert customers an exceptionally attractive machine concept.

Using different recyclable films on a single line

Depending on their consistency and ingredients, baked goods and confectionery call for packaging with various barrier functions. With the Schubert Flowpacker, manufacturers who would like to quickly switch between flowpack films with different properties benefit from the most suitable sealing technology. It enables both recyclable mono-plastic films and paper-based flow-wrapping films to be used in a single machine. Schubert will demonstrate this with a system that combines an ultrasonic unit for longitudinal sealing with a flexible cross-sealing unit. The cross-sealing is performed either by a box motion unit with ultrasound or via rotating sealing jaws with heat sealing.