An automatic silkscreen-printing machine for decorating up to 10 colours in UV ink on multi-format containers, Servobottle by Omso has always been an eco-friendly solution. Since its design stage, the replacement of mercury lamps with LED lamps had made it possible to reduce heat transmission, cut the energy consumption of the LED lamps themselves by approx. 80% as well as the CO2 emissions in the environment, lower the ozone production to zero and eliminate the need for mercury disposal.

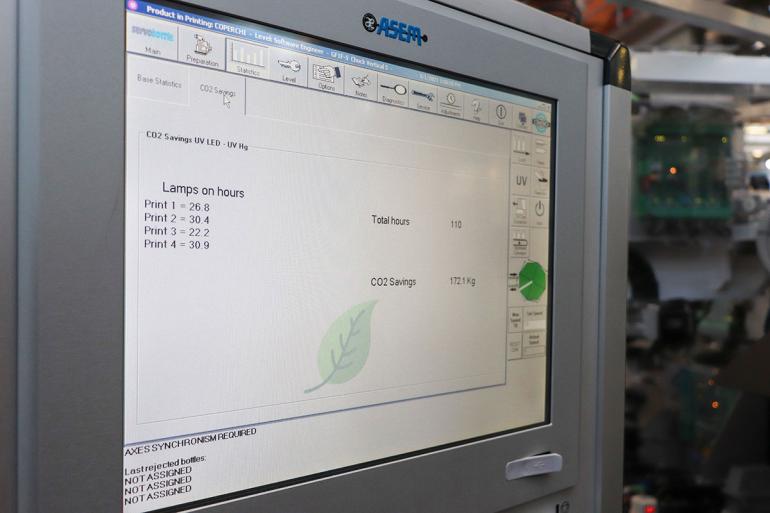

The “CO2 savings” page has been implemented in the Statistics section in the last Software Upgrade, where it is possible to see live how many CO2 Kgs are saved and, as a result, not released into the environment while the machine is running. This data is obtained comparing the energy consumption required for the functioning of the LED lamps with the one required for mercury lamps; the difference obtained corresponds to the energy savings; this information is then converted in CO2 kilogrammes saved, thus making the machine even more eco-friendly.

This improvement stems from the reflection that a green product is not only defined by selecting less impactful materials, such as recycled or bio-plastics, but also by an optimised and sustainable production cycle. This innovation will be implemented in all new Omso machines, and can be integrated right now in the machines already on the market as well: a software update is only required.