Sabic, a global leader in the chemical industry, demonstrated at K 2022 in Düsseldorf on October 19-26, how advanced polymer chemistry is making a distinct difference to reduce its climate impact. Under the theme of ‘Making the change real’, the company’s solutions on display emphasize two key areas: accelerating the implementation of a circular plastics economy, and creating a clean-air economy by driving the transition to product electrification.

Sabic’s portfolio of advanced material and technologies to help the packaging value chain increase sustainability and reduce waste without compromising food safety or product performance is focused on five areas:

• Reduce waste: innovative solutions designed to minimize waste and enable 100% recyclability and light weighting

• Certified circular solutions: high-quality polymers with ISCC PLUS mass-balance accredited feedstock content from thermo-chemically processed, hard-to-recycle post-consumer mixed plastics

• Closed-loop collaborations & recycling of ocean plastic: value chain partnership projects to maximize the circularity of valuable used plastics within application segments

• Certified renewable solutions: use of materials with ISCC PLUS mass-balance accredited bio-based feedstock content that are not in direct competition with the human food chain and help reduce potential effects of climate change

• Consumer appeal & functionality: differentiated, durable applications with lighter, recyclable design and enhanced shelf appearance as well as greater functionality

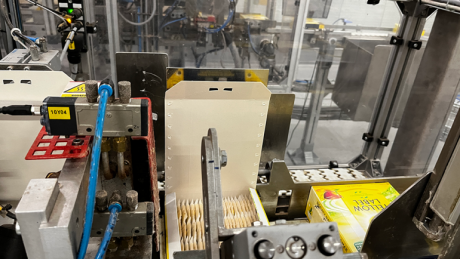

An outstanding example of closed-loop collaboration success in the flexible packaging is with Mars for Kind healthy snack bar wrapper manufactured from flexible BOPP film with using certified circular Sabic PP for food contact. The sustainable mono-material packaging solution facilitates end-of-life recycling in existing collection and conversion operations without compromising high-speed processing or product quality.

Another close collaboration of Sabic with Covestro, a new fully recyclable stand-up pouch made with Sabic BOPE material and including Covestro’s heat-resistant coating resin technology. This transparent coating, currently in trial phase, the solution has been tested and validated, offering a broader sealing temperature window when processing on form fill and seal (FFS) lines for flexible packaging as it prevents both, film shrinkage and film sticking to heat seal bars during FFS. The new PE based high-performance, recyclable; mono-material stand-up pouch supports the drive to achieve a circular economy for flexible packaging, as it is a viable solution to replace PET or PA laminates in incumbent solutions.