Valco Melton’s palletizing solution is designed to minimize product damage while avoiding unnecessary costs related with the use of stretch film wrap. Whether you are working with corrugated boxes, bags, sacks, or PET bottles packages, Valco Melton’s palletizing adhesive gluing system applies the precise amount of adhesive required to make sure that your products are safely stacked for transportation and delivery to your customers.

The use of anti-slip hot melt adhesive is an efficient and cost-effective alternative that replaces, completely or partially, the use of stretch wrap. This reduces consumable costs up to 80%, and takes a step towards a more sustainable supply chain, with the reduction or elimination of polluting waste (stretch wrap or thermo-shrink film). Furthermore, for certain end products, hot melt palletizing eliminates the need to use carton corners, which reduces further the use and stock of consumables, bringing additional savings.

These palletizing systems are also an ideal solution for PET bottle packages. Even though, on specific cases, a small amount of stretch wrap might still be needed to prevent dust from getting in contact with the final product, important savings come from eliminating the use of intermediate carton liners between the layers of stacked bottles.

To avoid any damage on corrugated boxes, sacks, or shrinkable film, Valco Melton's systems use low tack adhesives, which allow products to be restacked several times while keeping their adhesion capabilities. No need to discard amounts of stretch wrap for restacking processes.

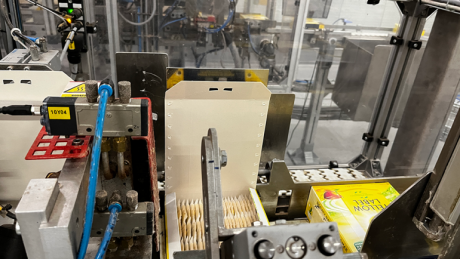

Our complete solution includes a selection of adhesive melters in different tank sizes to adapt to each process requirements and adhesive types. Hot melt applicators for dot, bead or spray applications, and a pattern control which may be external or integrated in one of our adhesive melters are the other system components supplied to complete the package for new or existing palletizing lines. The system remains independent to the line however, so that it can be moved to another location at any time, without the need to stop the production line – neither for the first installation, nor for subsequent location changes.

Valco Melton’s EC Series and NC Series standard hot melt units offer a very easy configuration to adapt the system to any production line requirement. Additionally, EC Series units features an integrated pattern control, directly accessible from its intuitive control panel.

Complete the configuration with MKF Series Insulated hot melt applicators or MZ Series Spray hot melt guns. Both suitable for high speed lines, they easily adapt to any machine structure, guaranteeing a clean end-of-line packaging.