As part of its Trucircle programme, Sabic has developed recycled plastic packaging that promotes the circular economy.

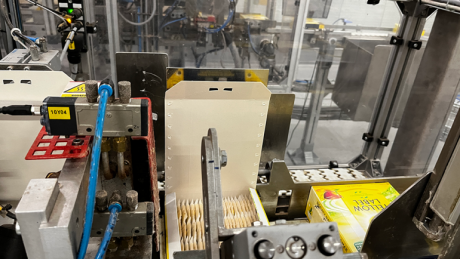

Source, one of Saudi Arabia's leading bakery operators, has introduced certified circular polyethylene bread bags for its Arabic oat bread. The bags are produced by Napco National, a Saudi Arabian manufacturer of flexible films and packaging, using two grades of food contact certified low-low-density polyethylene (LLDPE) resin from the Trucircle portfolio.

Following the launch of the joint project in March 2023 and the successful completion of the trial phase at Napco, Fonte began introducing the flexible bags in stores across Saudi Arabia.

These new bags contain 100% recycled raw materials from post-consumer mixed plastics, which are converted into pyrolysis oil in an advanced recycling process. Sabic then uses the oil to produce new polymers of the same quality as traditional virgin plastics at the company's plant in Jubail, Saudi Arabia.

Mohammed Binmahfoodh, CEO of Masdar Alhayat for Food Industries (Source), said:

As the availability of high quality recycled plastics in Saudi Arabia increases, we look forward to replicating the success of this project with Sabic and Napco for other food packaging in Saudi Arabia.

Chadi Radi, Managing Director of Napco National, said:

Napco is committed to promoting sustainable packaging in various sectors of the plastics industry in Saudi Arabia and throughout the Gulf region. We recognise the urgent need to address environmental challenges and are committed to helping our customers achieve their sustainability goals. Through our innovative approach, we seek to develop packaging that minimises environmental impact, promotes circularity and maximises the life cycle value of plastics. At Napco National, we welcome the advanced recycling pathway offered by Sabic as an opportunity to contribute to the circularity of plastics in flexible packaging films.