State-of-the-art measurement technologies, artificial intelligence, and a strong network of partners are the key ingredients of the SpecReK project, led by Basf with support from the German Federal Ministry of Education and Research (BMBF). In collaboration with Endress+Hauser, TechnoCompound, and the Universities of Bayreuth and Jena, the project aims to significantly improve the mechanical recycling of plastics, thus strengthening the circular economy.

Thanks to advanced spectroscopic techniques and the use of artificial intelligence (AI), the project aims to precisely identify the composition of plastic waste during the recycling process. Spectroscopy will allow for the analysis of material interactions with light to gather information on their chemical structure, while AI algorithms will process data in real-time to suggest modifications to the recycling process or the addition of additives. This approach will ensure higher quality recycled materials, increasing their suitability for producing high-value products.

We do not currently have the necessary analysis tools to determine during processing exactly which components are contained in the mechanically recycled plastics. This information is needed, however, to evaluate and improve the quality of waste plastics. This will enable us to use more mechanically recycled plastics to produce high-quality products and to make recycling processes more efficient and sustainable,

explained Bernhard von Vacano, head of the Plastics Circularity research program at Basf.

Strengthening the Plastic Circular Economy

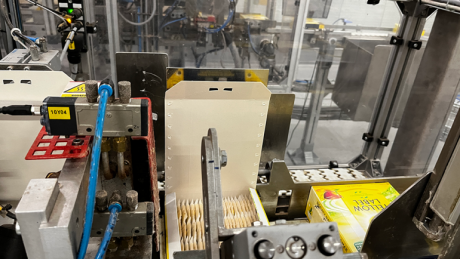

Currently, most plastic waste is mechanically recycled, a process involving collection, sorting, shredding, cleaning, and melting. However, the melted material may contain various types of plastics, additives, and contaminants, often resulting in recycled products that do not meet high standards. SpecReK aims to address this issue, responding to the growing demand for high-quality recycled materials and regulatory requirements.

With the increasing demand for high-quality recycled materials, and given the current legal framework, it will be crucial to perfectly understand the material properties and composition of mechanically recycled plastic waste and to optimize the process. In this way, we will strengthen the circular economy,

von Vacano said.

The project, with a total investment of 2.2 million euros, is funded two-thirds by the BMBF's quantum systems research programme and one-third by the partners. The collaboration between Basf and its partners aims not only to improve mechanical recycling but also to strengthen the entire circular economy system.

Chemical and Mechanical Recycling

When mechanical recycling is too complex or technologically unfeasible, chemical recycling offers a viable alternative to reintroduce plastics into the production cycle. Basf recognises the importance of both methods and continues to invest in optimising these complementary technologies, contributing to a more sustainable management of plastic materials.